Custom-Made Reading Glasses for Your Brand

We specialize in OEM/ODM manufacturing of RX-free reading eyewear — designed, prototyped, and produced based on your style, strength needs, and packaging preferences.

Why Choose Sailook for Custom Readers

Specialized in Private-Label Reader Manufacturing

- Custom designs developed to match your brand identity

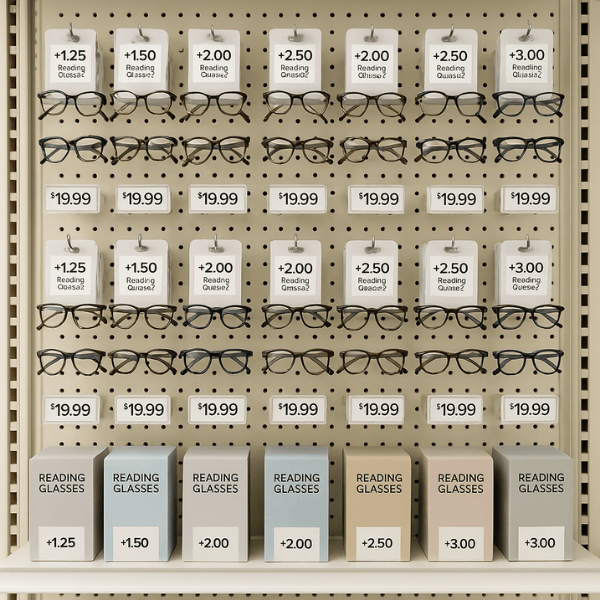

- RX-free demo lenses from +0.50 to +3.50

- Multiple strength options supported per model

- Material flexibility: acetate, TR90, titanium, stainless steel, etc.

- 10–20 day sampling + structured QC before shipment

What You Can Customize

From Design to Packaging — Fully Tailored to You

- Frame Design: Classic or trend-forward shapes — based on your specs or mood boards

- Material: Acetate, TR90, titanium, stainless steel, mixed options

- Lens Strengths: Standard RX-free lenses: +0.50 to +3.50 (0.25 steps)

- Branding: Custom logo via laser, pad print, or metal inlay, etc.

- Color/Finish: Solid, tortoiseshell, bi-color, transparent, matte/gloss, etc.

- Packaging: Custom retail boxes, pouches, barcode stickers, insert cards

Who We Serve

How We Work

From Idea to Delivery — A Seamless OEM Process

Share Your Brief or Concept

Send us your project brief, mood boards, target audience, or reference styles. Whether you have full technical drawings or just a rough idea, we can start from wherever you are.

Quotation & Material Proposal

We review your requirements and provide a detailed quotation, suggest suitable materials (acetate, TR90, titanium, etc.), and confirm lens strength options, color concepts, and packaging direction.

Prototyping & Sampling (10–20 Days)

Our in-house prototyping team creates your first samples with full customization. Sample lenses come in standard strengths or demo (RX-free) formats. You receive photo/video updates or physical samples for hands-on review.

Feedback, Refinement & Production

We collect your feedback, make necessary adjustments, and proceed to mass production only after final approval. Production schedules are transparent and adjustable per your timeline.

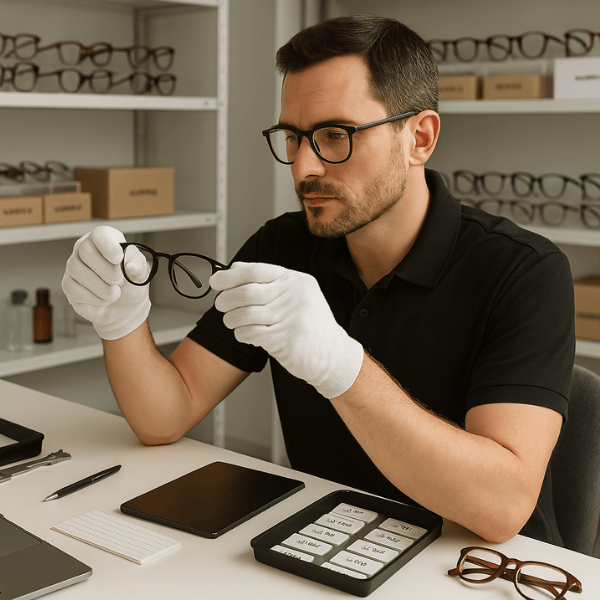

Final QC & On-Time Delivery

Before shipping, each batch undergoes structured QC — including fit, lens strength verification, logo accuracy, and finishing. Orders are packed per your labeling and shipping specs, and dispatched on time.

Frequently Asked Questions

It makes sense that you’ll have questions before you make a purchase of our custom reading glasses. So, we’ve listed some of our most commonly asked questions below. Explore our FAQ section and then reach out to us if you have any remaining questions.

Yes. Our reading glasses are pre-configured with standard magnification lenses ranging from +0.50 to +3.50. All lenses are RX-free and made from clear, distortion-free optical materials.

Absolutely. We support split orders — for example, one model with 5 strengths — to help you cover different customer needs while managing inventory efficiently.

We support custom logos on temples, lenses, or packaging; multiple colorways per model; different frame shapes and materials; and branded retail packaging including cases, cloths, inserts, and barcode labeling.

Get A Custom Reading Glasses Quote

Have more questions or are just interested in an estimate for your custom reading glasses? If so, please reach out to us using the form below.