What is Acetate Material?

Cellulose acetate, often called the “organic cotton of eyewear,” is a premium, plant-based material that has revolutionized the eyewear industry. Derived from renewable resources such as cotton and wood pulp, acetate combines natural sustainability with unmatched versatility, making it a preferred choice for crafting high-quality eyewear frames.

Much like organic cotton in fashion, cellulose acetate represents a blend of natural origins and superior quality in eyewear. Whether for bold, fashion-forward designs or timeless classics, acetate offers a sustainable, stylish, and high-performance foundation for creating exceptional eyewear collections.

Features of Acetate Eyewear

- Eco-Friendly and Sustainable:

Made from biodegradable and renewable raw materials, acetate aligns perfectly with modern environmental consciousness, offering a greener alternative to petroleum-based plastics. - Luxurious Finish:

Acetate frames are celebrated for their smooth, polished texture and vibrant color patterns, exuding a level of sophistication that stands apart in the market. - Durability Meets Comfort:

Despite being lightweight, acetate frames are exceptionally durable, resistant to impact and warping, ensuring long-lasting use while remaining comfortable for all-day wear. - Customizable Designs:

Acetate’s ability to hold intricate colors, textures, and patterns allows for endless design possibilities, catering to diverse aesthetic preferences and brand identities. - Hypoallergenic Properties:

Being free from harsh chemicals, acetate is an excellent choice for sensitive skin, ensuring safe and comfortable use.

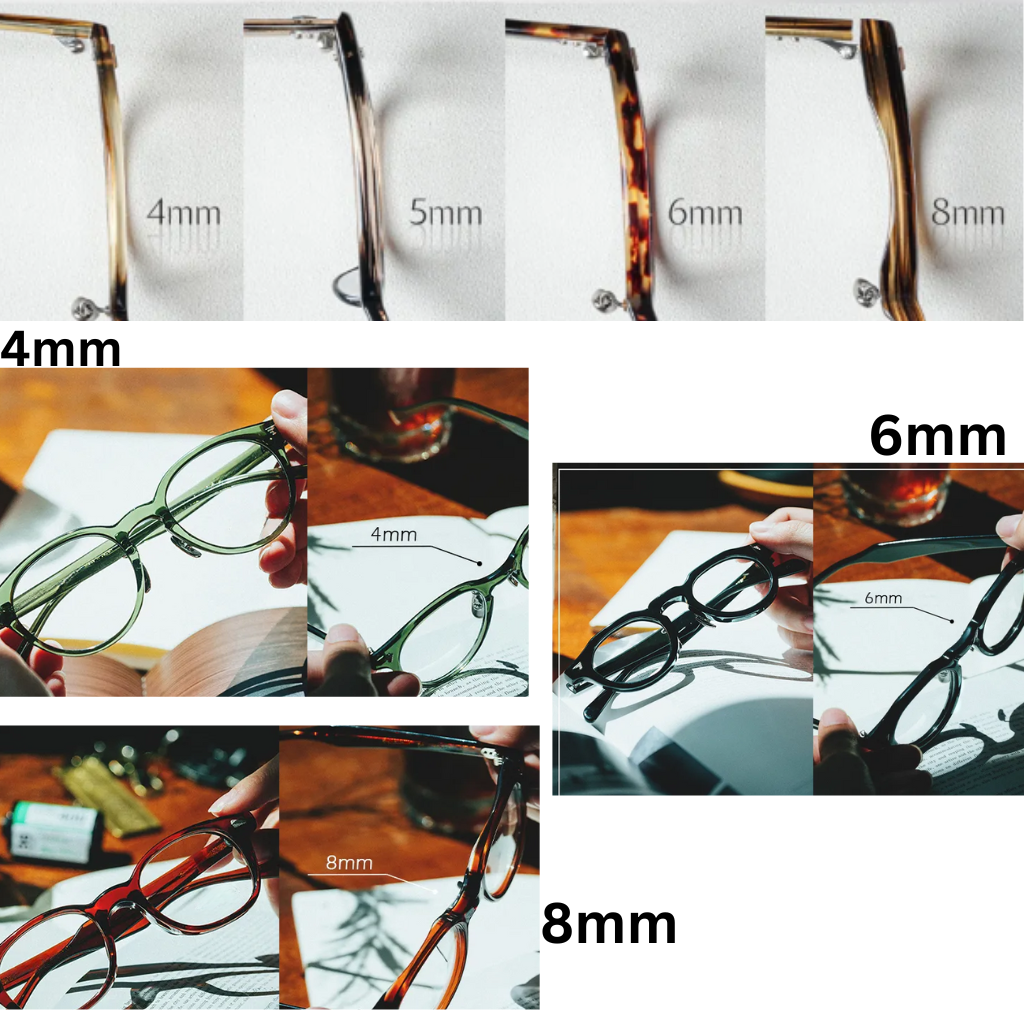

Thickness of Acetate

Find the Perfect Acetate Thickness for You

1. Simple Elegance (Thickness: 4mm)

Ideal for those new to acetate eyewear.

- Light and Comfortable: No burden when wearing, especially suitable for all-day use.

- Simple and Versatile: Perfect for daily commutes and casual occasions, adding a subtle touch of style.

- Recommended for: First-time eyewear users or those who prefer a lighter, minimalist style.

2. Balanced Appeal (Thickness: 5mm & 6mm)

For those seeking the perfect balance between subtlety and personality.

- Moderate Boldness: Showcases style without being too attention-grabbing.

- Versatile Design: Easily transitions between formal and casual settings.

- Recommended for: Those with some eyewear experience who want to enhance their style.

3. Bold Statement (Thickness: 8mm)

Express individuality and become the center of attention.

- Visual Impact: Unique design that conveys strong personality.

- Distinctive Style: Perfect for those who want to stand out in a crowd.

- Recommended for: Fashion-forward individuals who enjoy experimenting with bold and daring designs.

Acetate Eyewear: A World of Color Options

Acetate eyewear offers endless color options, from classic tones to bold, modern shades.

Color & Patterns

- Classic & Trendy Shades: Tortoiseshell, black, vibrant blues, and reds.

- Unique Patterns: Marble, plaid, and more.

Premium Materials

- Mazzucchelli Acetate: High-quality, durable, and stylish.

- Domestic Options: Affordable, consistent quality.

Eco-Friendly Options

- Biodegradable Acetate: Sustainable and plant-based materials.

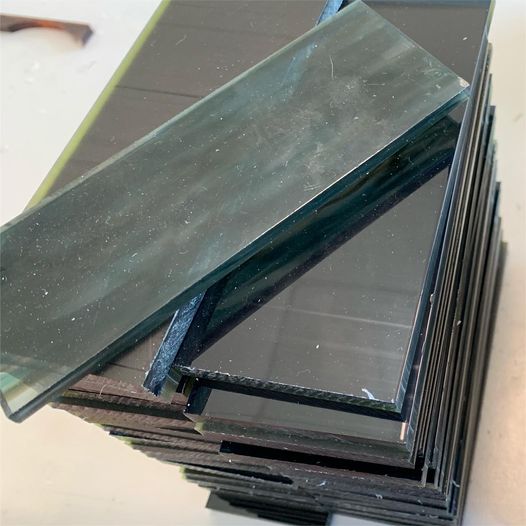

Key Stages in Acetate Eyewear Production

Below are some of the essential steps in crafting premium acetate eyewear. These selected processes highlight the craftsmanship, precision, and technology involved in transforming raw acetate sheets into stylish and durable frames.

Step 1: Acetate Sheet Preparation

Raw acetate material is mixed with organic colors and acetone to create a paste. This paste is rolled into thin sheets, layered for complex coloration, and molded into large blocks. After curing in kilns for several weeks, these blocks are sliced into sheets for use.

Step 2: Thermal Molding

The acetate sheets are heated and molded into large blocks to stabilize the material and achieve the desired thickness and density. This process enhances the durability and flexibility of the material, preparing it for precise cutting and shaping in subsequent steps.

Step 3: Cutting and Forming

Frames are precisely cut using CNC machines based on technician input. Frame components are then hand-finished, curved, and fitted with core wires, hinges, and nose pads.

Step 4:Tumble Polishing

Frame components are placed in barrels with wood chips and small stones and tumbled for hours to smooth surfaces.

Step 5: Hand Polishing

Each frame is individually buffed by skilled technicians to achieve a polished, glossy finish that highlights the acetate’s texture.

Step 6: Component Assembly

Technicians attach hinges, rivets, and screws to connect the frame and arms. Nose pads and other components are also added at this stage.

Step 7: Lens Installation

Lenses are carefully inserted into the frames. This step requires precision to ensure the lenses fit securely and maintain the frame’s alignment.

Step 8: Final Inspection and Packaging

Each pair of glasses undergoes a final quality check to ensure alignment, durability, and overall appearance. After cleaning and adjustment, the frames are carefully packaged for shipment.

Tailored Acetate Eyewear for Your Brand

At Sailook, we offer end-to-end customization services to bring your vision to life. From design to production, we tailor every detail to align with your brand’s identity.

Frame Shape & Style: Choose from classic, modern, or unique shapes such as round, square, cat-eye, and more.

Material Selection: High-quality acetate, mixed materials, or eco-friendly options.

Color & Pattern: Offer hundreds of vibrant colors, patterns, or custom designs.

Branding Options: Engrave your logo or signature details on frames.

Lens Customization: Include polarized, tinted, or prescription lenses.

Contact With Us

Write A Message