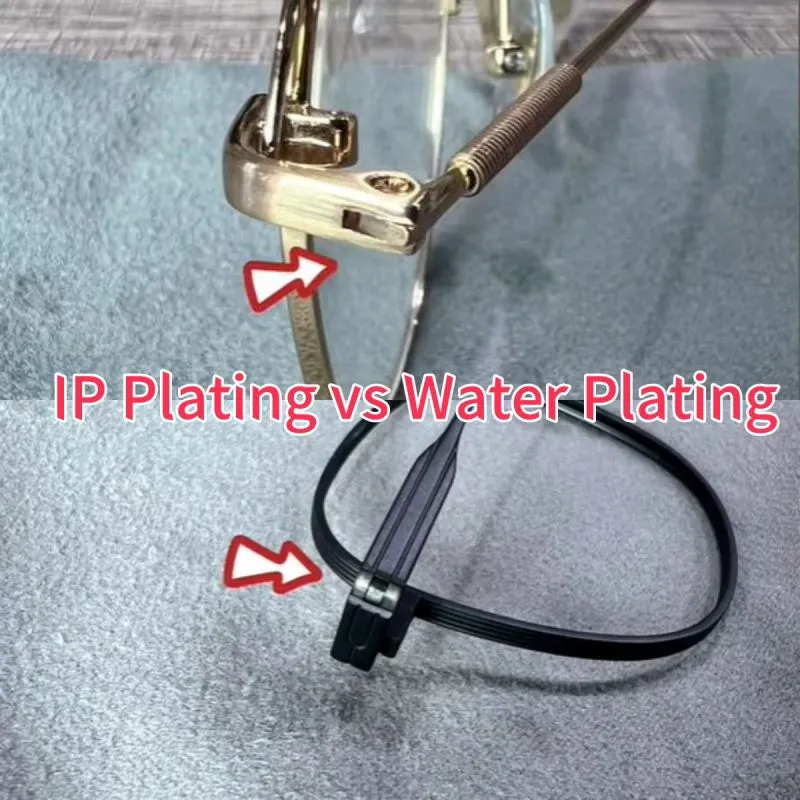

Electroplating plays a crucial role in eyewear manufacturing. Two common methods—vacuum plating and water plating—offer different advantages and limitations. How do they compare, and which is the best choice for eyewear frames?

Vacuum plating provides high durability, environmental safety, and color variety, while water plating offers a cost-effective alternative for specific materials. This article explores their differences, processes, and applications.

Understanding the differences between these two plating methods can help eyewear manufacturers make informed decisions. Let’s dive deeper into their principles, applications, and challenges.

What Are the Principles Behind Vacuum Plating and Water Plating?

Electroplating involves depositing a metal layer onto a surface. The method used affects durability, aesthetics, and cost.

Vacuum plating relies on a vacuum environment to deposit metal coatings, while water plating uses an electrochemical process to coat frames.

Key Differences in Plating Methods

| Feature | Vacuum Plating | Water Plating |

|---|---|---|

| Process | Physical vapor deposition in a vacuum | Electrochemical deposition in liquid |

| Material Compatibility | Metals, alloys | ABS, ABS+PC plastics |

| Color Options | Wide variety (including rainbow and gradient) | Limited (silver, gunmetal, gold) |

| Durability | High resistance to wear | Lower resistance to wear |

| Environmental Impact | Eco-friendly | Can involve toxic chemicals like hexavalent chromium |

Vacuum plating is preferred for high-end eyewear due to its durability and aesthetic flexibility, while water plating is used in budget-friendly frames.

How Does Vacuum Plating Work for Eyewear Frames?

Vacuum plating involves multiple stages, from pre-treatment to final coating.

This method creates high-quality, scratch-resistant, and heat-resistant coatings, making it ideal for premium eyewear brands.

Steps in the Vacuum Plating Process

1. Surface Preparation

- Frames are cleaned and degreased to ensure adhesion.

- Pre-coating is applied to enhance durability.

2. Vacuum Deposition

- A vacuum chamber removes air to create a controlled environment.

- Metal vapor adheres to the frame surface, forming a thin coating.

3. UV Coating Application

- UV coatings improve scratch resistance and adhesion.

- Enhances gloss and durability.

| Advantage | Description |

|---|---|

| Color Variety | Can achieve multiple colors, including gradients. |

| High Durability | More wear-resistant than water plating. |

| Eco-Friendly | Uses non-toxic materials and meets environmental standards. |

| Heat Resistance | Maintains coating quality at high temperatures. |

Vacuum plating is commonly used in high-end eyewear to enhance quality and design appeal.

How Does Water Plating Work for Eyewear Frames?

Water plating (electroplating) is a cost-effective method that deposits a metal layer onto plastic frames.

This process is simpler and cheaper but has limitations in durability, color variety, and environmental impact.

Steps in the Water Plating Process

1. Frame Preparation

- ABS and ABS+PC frames are cleaned to remove impurities.

- A conductive layer is applied to enable plating.

2. Electroplating Process

- Frames are submerged in an electrolyte bath.

- Electric current deposits a metal layer onto the frame.

3. Final Coating

- A protective topcoat is applied to prevent oxidation.

| Feature | Description |

|---|---|

| Cost-Effective | Lower production costs than vacuum plating. |

| Simple Process | Requires less specialized equipment. |

| Limited Durability | More prone to scratches and wear. |

| Environmental Issues | Uses hazardous chemicals like hexavalent chromium. |

Water plating is mostly used for budget eyewear but has environmental concerns and lower longevity.

How Do Vacuum Plating and Water Plating Compare?

Comparing these two methods helps manufacturers choose the best option based on cost, performance, and environmental factors.

Vacuum plating excels in durability and eco-friendliness, while water plating remains a viable low-cost alternative for plastic frames.

Comparison by Key Factors

| Factor | Vacuum Plating | Water Plating |

|---|---|---|

| Cost | Higher | Lower |

| Durability | High (scratch-resistant) | Low (prone to wear) |

| Color Variety | Extensive | Limited |

| Material Compatibility | Metals, alloys | Plastics (ABS, ABS+PC) |

| Environmental Impact | Eco-friendly | Can involve toxic chemicals |

For premium eyewear, vacuum plating is the better choice, while water plating remains useful for cost-sensitive products.

What Are the Future Trends in Eyewear Plating Technology?

Advancements in plating technology focus on sustainability, automation, and material innovation.

New techniques like trivalent chromium plating and nanocoatings are gaining traction, offering safer and more efficient alternatives.

Key Future Developments

1. Eco-Friendly Plating

- Trivalent chromium replaces toxic hexavalent chromium.

- Reduced waste and energy consumption.

2. Automated Processes

- AI-driven plating systems optimize efficiency.

- Reduces manual labor and defects.

3. Advanced Coating Materials

- Nanocoatings improve scratch resistance.

- Enhances UV protection for eyewear frames.

Sustainability and efficiency will shape the future of eyewear plating.

Conclusion

Vacuum plating offers superior durability, aesthetics, and environmental benefits, making it ideal for high-end eyewear. Water plating remains a cost-effective option but has limitations in durability and eco-friendliness.