Sunglasses are more than just a stylish accessory; they play a crucial role in protecting our eyes from harmful UV rays. But have you ever wondered how sunglasses are made? This article takes you through the entire sunglasses manufacturing process, from selecting materials to assembling the final product. Whether you’re in the eyewear industry or simply curious about the craftsmanship behind the lenses you wear, this guide will provide a comprehensive understanding of how sunglasses are created. Let’s dive into the intricate steps of manufacturing these essential accessories!

1. How are Sunglasses Made?

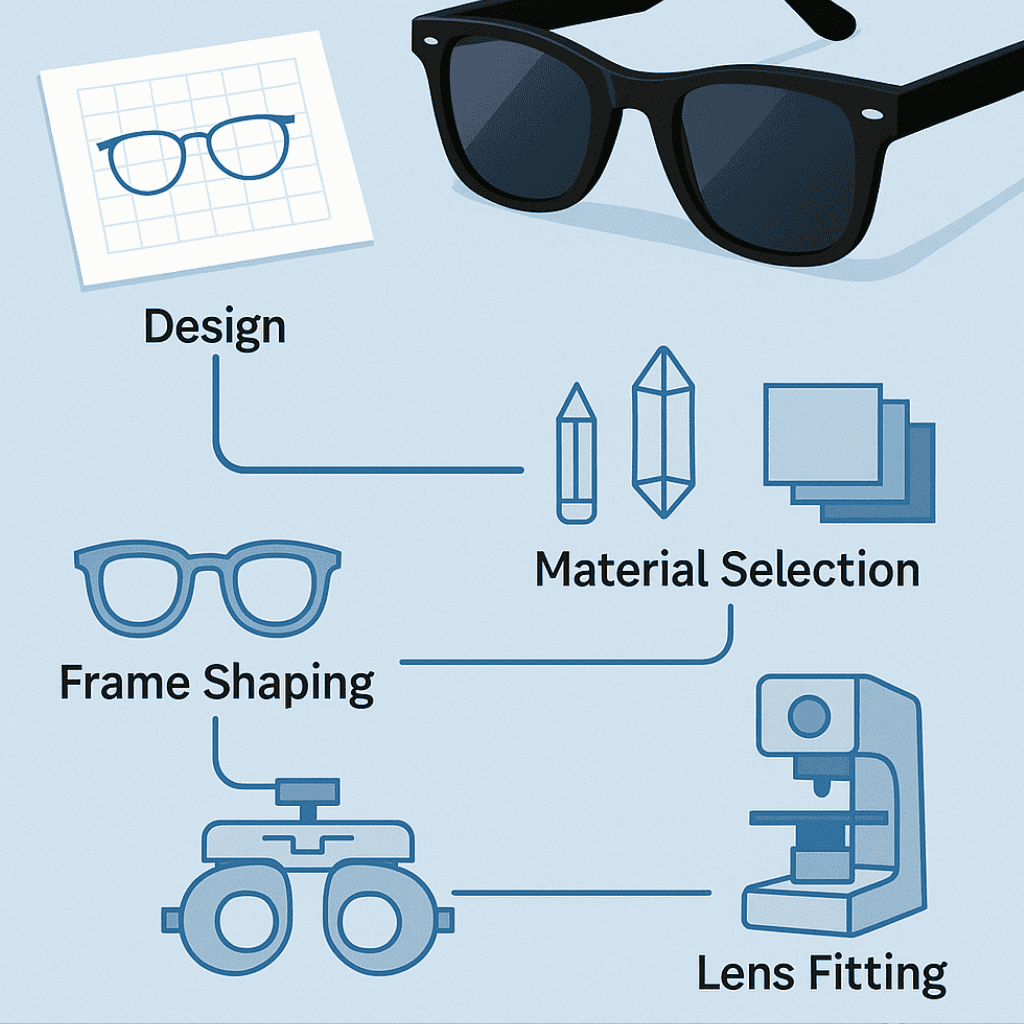

Creating sunglasses is a detailed and systematic process that combines fashion and function. It involves several stages, from designing frames and lenses to assembling the final product. What’s the real story? Sunglasses are not just about their appearance; they are carefully crafted to meet safety standards, offer protection, and ensure durability.

The first step in the manufacturing process is the design phase, where designers create the look of the frame and decide on the material. Once the design is finalized, manufacturers source the materials, which can include acetate, metal, titanium, or plastic. Here’s the kicker: each material has different properties, affecting the sunglasses’ weight, flexibility, and durability. After material selection, the frame is cut, molded, and polished to achieve the desired shape.

Next, lenses are added. Lenses can come in a variety of styles, including polarized, mirrored, or tinted. Ready for the good part? Polarized lenses are particularly popular for their ability to reduce glare, providing better clarity and protection from UV rays.

Finally, the frames and lenses are carefully assembled, ensuring that the fit is perfect, and that each pair of sunglasses meets quality control standards. The result is a fashionable yet functional eyewear accessory that helps protect the eyes while complementing personal style.

| Step | Description |

|---|---|

| Design | Designers create the frame and select materials |

| Material Selection | Acetate, metal, titanium, and plastic are used |

| Frame Cutting | The frame is shaped and polished |

| Lens Assembly | Lenses are added based on style (polarized, tinted, mirrored) |

2. What Materials are Used to Make Sunglasses?

The materials used in sunglasses play a significant role in their durability, comfort, and style. What’s the real story? Different materials offer unique benefits, which is why sunglasses manufacturers carefully select the right ones based on the desired product.

The most common material for frames is acetate, a plant-based plastic that is durable and lightweight. Acetate frames are also highly customizable, available in various colors and patterns, making them a favorite for fashion-conscious consumers. But here’s the kicker: acetate frames are hypoallergenic and offer a high degree of comfort.

Another popular material is metal, often used for higher-end sunglasses. Metal frames are sleek, durable, and stylish, providing a modern, sophisticated look. Stainless steel and titanium are the most common metals used, as they are resistant to corrosion and offer a lightweight, strong frame.

What’s next? Plastic frames are also widely used for their affordability and variety. Plastic frames can come in multiple colors, and are often used for trendy designs or for sunglasses made for mass-market consumption.

For lenses, there are several options. Polarized lenses are often used to reduce glare from reflective surfaces like water or roads. UV-protection lenses are essential in preventing sun damage to the eyes, while mirrored lenses offer an added layer of protection and style.

| Material | Benefits |

|---|---|

| Acetate | Lightweight, customizable, hypoallergenic |

| Metal (stainless steel, titanium) | Durable, corrosion-resistant, sleek design |

| Plastic | Affordable, variety of styles, mass-market appeal |

| Polarized Lenses | Reduces glare, better clarity |

| UV-Protective Lenses | Protects eyes from harmful UV rays |

3. What are the Key Stages in the Sunglasses Manufacturing Process?

The process of manufacturing sunglasses is more intricate than many people realize. Here’s where it gets interesting. Each pair goes through multiple stages to ensure both quality and functionality. The key stages are design, frame creation, lens fitting, and final inspection.

Designing the Frames: The design phase involves creating detailed specifications for the sunglasses, including the shape, color, and material of the frames. Designers use advanced computer-aided design (CAD) software to create prototypes before moving to production. But here’s the kicker: CAD helps designers visualize their ideas and make adjustments quickly.

Frame Production: After the design is finalized, manufacturers move on to the frame creation stage. This includes cutting, molding, and polishing the frame to the desired shape. Ready for the good part? If acetate is the material of choice, it is heated and shaped into molds to form the frame. The frame is then polished to give it a smooth, glossy finish.

Lens Fitting: Once the frame is complete, the lenses are inserted into the frame. What’s next? Lenses are carefully cut to match the frame shape. Manufacturers may also apply coatings to the lenses, such as anti-scratch, UV protection, or polarization.

Final Inspection and Testing: Once the frame and lenses are assembled, sunglasses undergo a rigorous quality control process. What’s the real story? Each pair is checked for durability, fit, and lens quality to ensure it meets safety standards before being shipped out.

| Stage | Description |

|---|---|

| Design | CAD software is used to create prototypes |

| Frame Production | Cutting, molding, and polishing the frame |

| Lens Fitting | Lenses are cut and coated for protection |

| Quality Control | Final inspection ensures durability and fit |

4. How are Sunglass Frames Designed?

Designing sunglasses frames is an art in itself. What’s the real story? Sunglasses designers focus on both aesthetics and function, ensuring the frames not only look good but also fit comfortably and last long. Frames are designed using specialized software, which helps visualize the finished product before any manufacturing begins.

Ready for the good part? Designers often begin with a concept sketch or mood board. This step involves considering fashion trends, consumer preferences, and the intended purpose of the sunglasses. For example, luxury sunglasses might feature sleek metal frames, while casual sunglasses might have colorful acetate frames.

Once the concept is settled, CAD software is used to create 3D models. These models allow designers to experiment with different shapes, materials, and sizes to ensure the frame will be both functional and stylish. But here’s the kicker: CAD allows for precise measurements, ensuring the final frame will fit perfectly around the nose and ears.

Here’s the catch: Once the frame is designed digitally, a prototype is created. This allows manufacturers to test the comfort, fit, and look of the sunglasses before beginning mass production. Testing prototypes is an important step to avoid any design flaws.

| Design Phase | Tools and Process |

|---|---|

| Concept Design | Mood boards and sketching |

| 3D Modeling | CAD software to create detailed designs |

| Prototype Testing | Physical testing for comfort and fit |

5. How is the Frame Shaped and Crafted?

The process of shaping the frame involves turning raw materials into the sleek, stylish designs we wear today. What’s the real story? The shaping process includes cutting, molding, and polishing the frame to perfection. Let’s break it down.

For acetate frames, the material is first cut into blocks and then heated. Ready for the good part? Once softened, the acetate is placed into a mold, and pressure is applied to shape it into the desired frame. After cooling, the frame is carefully trimmed and polished to create the smooth edges and glossy finish.

What’s next? For metal frames, the process is slightly different. The metal is first cut into thin strips and then bent using a machine to form the basic shape of the frame. But here’s the kicker: The frame is then welded at the joints for extra strength, and the edges are polished to remove any sharp or rough spots.

Here’s the catch: Some frames use a combination of both acetate and metal. These hybrid frames are a trend in high-fashion sunglasses, offering the best of both worlds: the durability of metal with the lightweight comfort of acetate.

| Frame Type | Manufacturing Process |

|---|---|

| Acetate | Cut, heated, molded, polished |

| Metal | Cut, bent, welded, polished |

| Hybrid | Combination of acetate and metal |

6. What Role Does Lens Manufacturing Play in Sunglasses Production?

Lens manufacturing is an essential part of creating quality sunglasses. What’s the real story? Lenses are not just for improving vision but also for offering protection from harmful UV rays. There are several types of lenses used in sunglasses, including polarized, UV-protective, and mirrored lenses.

Here’s the kicker: Polarized lenses are particularly important because they reduce glare, making them ideal for outdoor activities such as driving or fishing. But here’s the catch: Polarization is achieved by adding a special coating to the lens, which blocks out horizontal light waves that create glare.

Another critical feature of lenses is UV protection. Ready for the good part? Lenses are coated with UV-blocking filters that protect the eyes from harmful ultraviolet rays, which can cause damage over time.

What’s next? Mirrored lenses, which have a reflective coating on the outside, provide added protection against the sun’s rays and are often seen in high-fashion eyewear. These lenses also offer a stylish look, making them a popular choice in trendy sunglasses.

| Lens Type | Features |

|---|---|

| Polarized | Reduces glare, improves clarity |

| UV-Protective | Protects from harmful UV rays |

| Mirrored | Reflective coating, stylish look |

7. How Are Lenses Attached to Sunglasses Frames?

Attaching lenses to frames is a delicate process. What’s the real story? Lenses must fit perfectly into the frames to ensure the sunglasses are comfortable and functional. But here’s the kicker: If the lenses aren’t properly attached, the glasses can become loose or even break under pressure.

There are two common methods for attaching lenses: gluing and inserting. In the gluing method, a special adhesive is applied to the inside of the frame before the lens is carefully placed into position. Ready for the good part? This method ensures the lens stays in place and is less likely to shift over time.

What’s next? In the inserting method, lenses are simply pressed into the frame. This method is typically used with frames that have grooves to hold the lenses securely. But here’s the catch: It requires precise fitting, so the lens stays in place without being too tight or loose.

| Method | Description |

|---|---|

| Gluing | Special adhesive to secure the lens |

| Inserting | Lenses pressed into frame grooves |

8. Why is Quality Control Important in Sunglasses Manufacturing?

Quality control is vital in the sunglasses production process. What’s the real story? Without proper quality checks, manufacturers can end up with faulty products, resulting in customer complaints and returns. But here’s the kicker: Sunglasses must meet both aesthetic standards and safety requirements.

During the quality control phase, the sunglasses are inspected for defects such as scratches, improper lens fitting, or loose frames. Ready for the good part? Manufacturers use a range of tools to ensure the sunglasses meet strict specifications, including optical testing for UV protection and fit testing for comfort.

What’s next? Quality control also includes testing the durability of the frames. For instance, acetate frames are checked for flexibility and strength, while metal frames undergo stress tests to ensure they can withstand daily wear and tear.

| Quality Check | What’s Tested |

|---|---|

| Lens Quality | UV protection, clarity, no scratches |

| Frame Durability | Flexibility, strength, and fit |

| Comfort | Fit, weight distribution, ease of wear |

9. How are Sunglasses Packaged for Distribution?

After sunglasses pass the quality control process, they are ready for packaging and distribution. What’s the real story? Packaging plays a crucial role in ensuring the sunglasses arrive safely at their destination. Ready for the good part? Protective packaging ensures the lenses don’t get scratched, and the frames don’t get bent during transit.

But here’s the kicker: Packaging can also serve as a branding opportunity. Many eyewear brands invest in high-quality, customized cases or pouches that reflect their image. What’s next? Some manufacturers also add a cleaning cloth to the packaging to help customers maintain their sunglasses.

Here’s the catch: Distribution methods vary depending on the scale of the brand. Larger brands may ship their products directly to stores or wholesalers, while smaller brands might sell through e-commerce platforms, sending individual orders directly to consumers.

| Packaging Element | Purpose |

|---|---|

| Protective Cases | Safeguards lenses and frames |

| Custom Branding | Enhances brand identity |

| Cleaning Cloth | Helps maintain lens quality |

10. How Does Sustainability Impact Sunglasses Manufacturing?

Sustainability is becoming an increasingly important factor in the production of sunglasses. What’s the real story? Consumers are more conscious than ever about the environmental impact of the products they buy, and eyewear brands are responding. But here’s the kicker: Using sustainable materials in the production of sunglasses is one of the most effective ways to reduce environmental harm.

Ready for the good part? Brands are now using eco-friendly materials like recycled plastic or bio-based acetate to create frames. These materials are not only sustainable but also durable and lightweight, making them ideal for high-quality sunglasses. What’s next? Sustainable packaging, such as cardboard cases or pouches made from organic cotton, is also becoming more common.

Here’s the catch: Reducing waste during the manufacturing process is another important factor. Many brands are working on ways to minimize their waste by optimizing production lines and reusing materials whenever possible.

| Sustainability Effort | Impact |

|---|---|

| Eco-friendly Materials | Reduces environmental footprint |

| Sustainable Packaging | Minimizes waste and enhances branding |

| Waste Reduction | More efficient use of resources |

11. What Innovations are Shaping the Future of Sunglasses Production?

Sunglasses manufacturing is constantly evolving. What’s the real story? Advances in technology are reshaping the way sunglasses are made, making the process more efficient, customizable, and innovative. Ready for the good part? 3D printing is one of the latest innovations in sunglasses production, allowing for custom frames and lenses to be produced on demand.

But here’s the kicker: Smart sunglasses are also gaining popularity. These eyewear devices integrate technology such as Bluetooth, voice assistants, or even head-up displays. What’s next? Virtual try-on technology is revolutionizing how customers shop for sunglasses, allowing them to see how different styles look on their faces before purchasing.

Here’s the catch: These innovations not only make sunglasses more functional but also add to their appeal, making them a must-have accessory for the tech-savvy consumer.

| Innovation | Description |

|---|---|

| 3D Printing | Custom frame and lens production |

| Smart Sunglasses | Integration of technology like Bluetooth |

| Virtual Try-Ons | Digital fitting for online shoppers |

12. How Do Sunglasses Manufacturers Meet Market Demand?

Sunglasses manufacturers must meet the growing demand for trendy and functional eyewear. What’s the real story? Manufacturers must stay on top of fashion trends, consumer preferences, and changing market conditions. But here’s the kicker: Managing production capacity is key to meeting deadlines while maintaining quality.

Ready for the good part? Brands that offer customization options often attract more customers. Consumers can select specific frame styles, lens colors, and even add logos to make their sunglasses unique. What’s next? Manufacturers also streamline their production processes to ensure quick turnaround times for large orders, which is essential for meeting market demand during peak seasons.

| Strategy | Impact |

|---|---|

| Customization | Attracts more customers with unique options |

| Efficient Production | Meets deadlines while maintaining quality |

| Trend Monitoring | Keeps products in line with consumer preferences |

13. What Are the Challenges in Sunglasses Manufacturing?

Sunglasses manufacturing presents several challenges, from quality control to staying on trend. What’s the real story? Ensuring that each pair meets high-quality standards is no small feat. But here’s the kicker: Production delays and material shortages can disrupt manufacturing timelines, affecting delivery to customers.

Ready for the good part? Manufacturers also face the challenge of sourcing sustainable materials while keeping costs manageable. What’s next? Ensuring consistency in mass production is another issue, as it’s crucial that each pair of sunglasses meets the same standards.

| Challenge | Solution |

|---|---|

| Production Delays | Streamline processes to avoid delays |

| Material Shortages | Work with multiple suppliers |

| Consistency in Quality | Use automated testing during production |

14. What Should You Look for When Choosing Sunglasses Manufacturers?

Choosing the right sunglasses manufacturer is a critical decision for eyewear brands. What’s the real story? The right manufacturer can help you bring high-quality products to market, on time and on budget. But here’s the kicker: You should consider factors like production capacity, experience, and ability to meet customization requests.

Ready for the good part? It’s also important to verify certifications like ISO and CE to ensure that the manufacturer meets international standards. What’s next? You should also ask for references from other clients to gauge the manufacturer’s reliability and track record.

| Factor | Importance |

|---|---|

| Production Capacity | Ensure they can handle large orders |

| Experience | Check for expertise in eyewear manufacturing |

| Certifications | Verify compliance with international standards |

15. Conclusion: How is the Sunglasses Manufacturing Industry Evolving?

The sunglasses manufacturing industry is evolving rapidly, driven by technological advancements and changing consumer preferences. What’s the real story? Manufacturers are embracing innovations like 3D printing, smart eyewear, and sustainable materials to meet the demands of the modern consumer. Ready for the good part? To stay competitive, sunglasses brands must keep up with these changes, ensuring that their products not only look good but also provide top-notch protection and functionality.

In conclusion, the future of sunglasses manufacturing is bright, with a focus on sustainability, technology, and customization. Here’s the catch: By choosing the right manufacturer and staying on top of trends, brands can continue to deliver high-quality eyewear that meets the needs of their customers.

FAQ Section

Q1: What is sunglasses manufacturing?

Sunglasses manufacturing is the process of designing, crafting, and assembling frames and lenses to create functional and stylish eyewear.

Q2: How do sunglasses manufacturers choose materials for frames and lenses?

Materials are selected based on durability, comfort, style, and functionality. Popular frame materials include acetate, metal, and plastic, while lenses can include polarized or UV-protective options.

Q3: How are lenses attached to sunglasses frames?

Lenses are attached using methods like gluing or inserting, ensuring a secure fit to maintain durability and comfort.

Q4: Why is quality control important in sunglasses manufacturing?

Quality control ensures that sunglasses meet safety standards, provide UV protection, and are durable enough for daily wear.