What Are Metal/Titanium Eyewear?

Metal and titanium eyewear combine robust durability with sleek, modern designs. Titanium frames are hypoallergenic, lightweight, and highly resistant to corrosion, making them ideal for premium collections.

Features of Metal/Titanium Eyewear

- Durability: Metal frames are resistant to bending and breaking, ensuring long-term use.

- Lightweight Comfort: Titanium frames weigh significantly less, providing all-day comfort.

- Corrosion Resistance: Titanium is impervious to rust, making it ideal for humid climates.

- Hypoallergenic Material: Titanium is skin-friendly, ideal for sensitive users.

- Flexible Design Options: Thin yet strong frames allow for intricate designs.

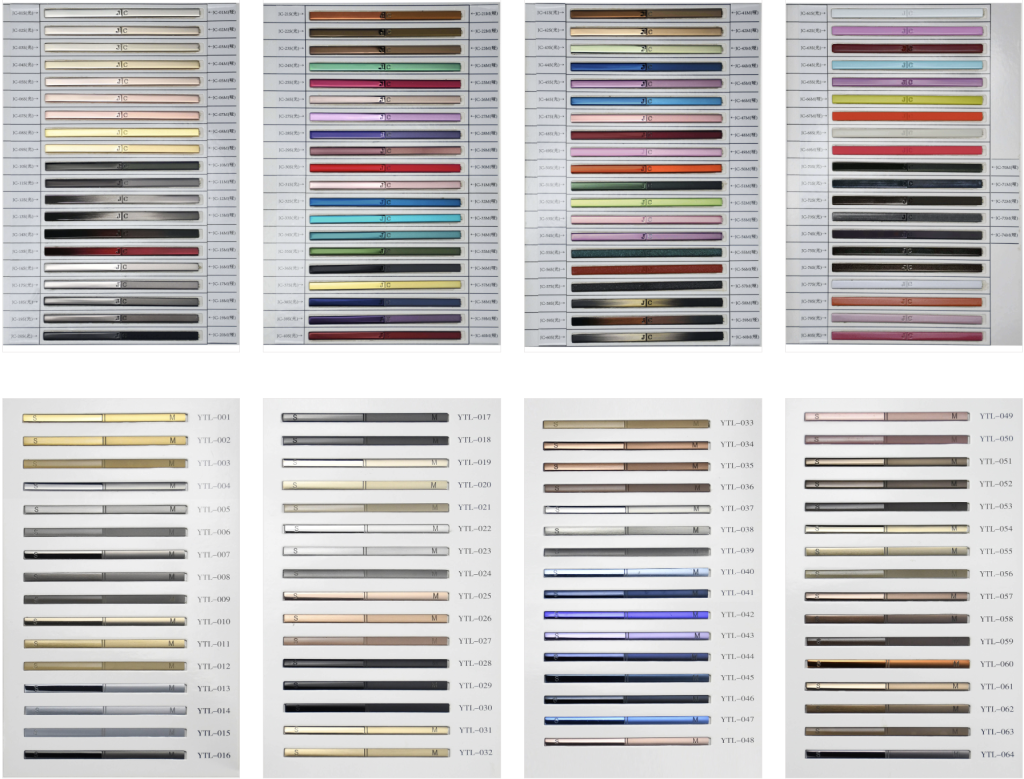

Electroplated Color Options for Metal Eyewear

Electroplating is a crucial step in crafting metal eyewear, offering a range of vibrant and durable color options that enhance both aesthetics and functionality. At Sailook, we provide a wide selection of electroplated finishes to meet diverse design preferences and brand requirements.

Electroplating color type:

1. Polished Metallic Finishes: High-shine finishes like gold, silver, and rose gold for a luxurious and elegant look.

2. Brushed & Matte Finishes: Subtle and understated finishes for a modern and sophisticated style.

3. Gradient & Multicolor Options: Unique gradient or multicolor electroplating for a contemporary and innovative aesthetic.

4. Custom Colors: Tailored electroplated colors to align with your brand identity or specific design needs.

Find Your Perfect Metal/Titanium Eyewear

From Timeless Classics to Customized Creations.

Key Stages in Metal/Titanium Eyewear

Eyewear Production

Below are some of the essential steps in crafting premium metal/titanium eyewear. These selected processes highlight the craftsmanship, precision, and technology involved in transforming raw acetate sheets into stylish and durable frames.

Step 1: Components Process

Metal frames mainly consist of rings, temples, bridges, arm pads, and hinges. The first step to manufacturing metal eyeglasses is making these metal components individually. There are 4 steps to get the components ready for the next processes: shaping, grinding, cutting, and bending.

Step 2: Soldering & Assembling

Connecting all the metal parts is the next job to do. Metal parts like rims, bridges, end pieces, and arm pads should be soldered together. The front and temples are connected with screws.

Step 3: Polishing

Polishing is so important for the quality of the metal eyewear. Both tumbling polish and hand polish are needed and the quality should be inspected right after them. Otherwise, the coloring processes will be affected causing irreversible results.

Step 4: Coloring

The colors of metal frames are added by plating and spray painting. Plated colors are much more firm but with very limited colors. On the other hand, spray painting provides almost all of the color options. Based on their own advantages and disadvantages, they were used for different purposes in the coloring process.

Step 5: Assembling

we assemble the non-metal parts like temple tips, nose pads, and lens. Then silk print and pack for the inspection.

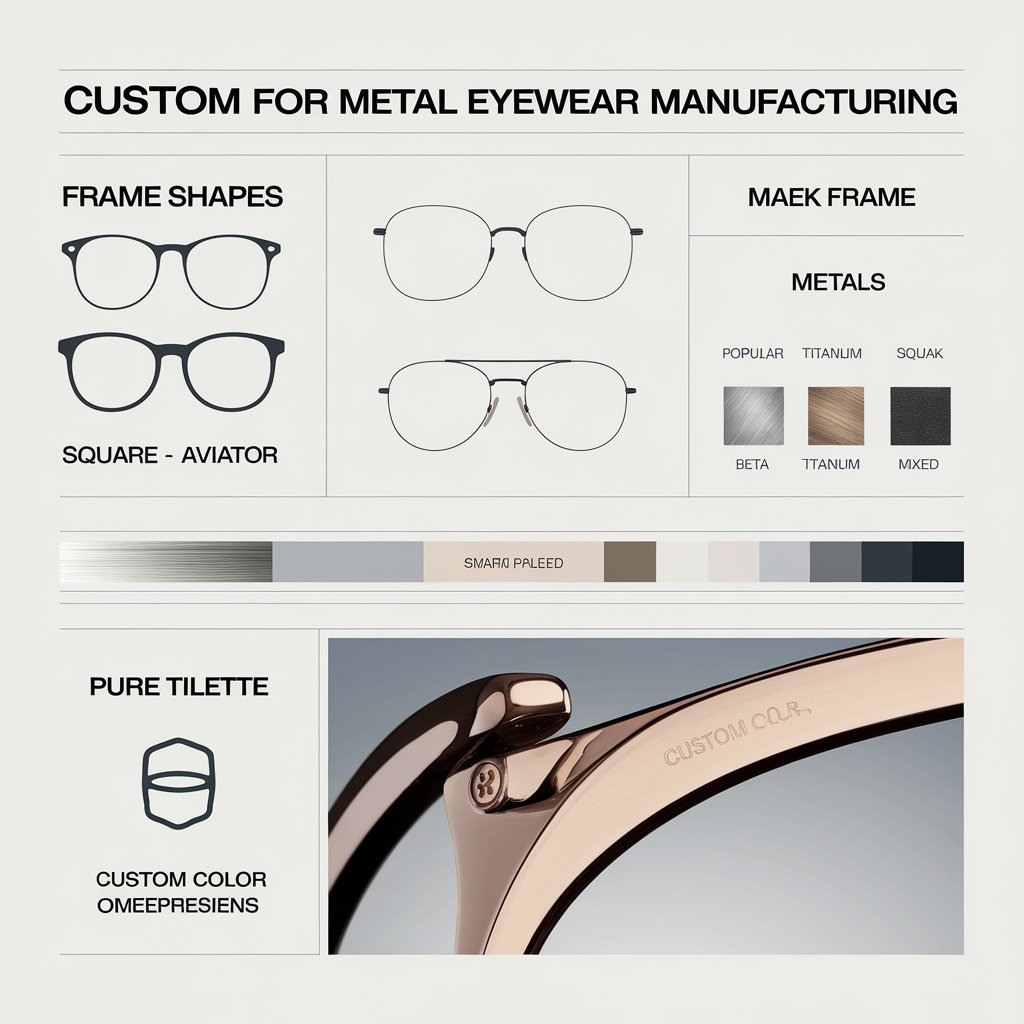

Customization Options

- Frame Shapes & Styles: Round, square, aviator, or custom designs.

- Material Options: Pure titanium, beta titanium, or mixed metals.

- Color Finishes: Brushed, polished, or custom colors.

- Branding: Custom logos and engravings for private labels.

Please contact us directly for the customized projects.

Contact With Us

Write A Message